What is rapid prototyping?

Rapid prototyping is a method for quickly and cost-effectively taking product designs and turning them into real working products. Rapid prototyping has advanced over the last 10 years at an astonishing rate and has allowed more people to quickly and easily bring their ideas to reality.

There are many methods for rapid prototyping, but the most common which has exploded is 3D printing or additive manufacturing.

So what is additive manufacturing?

In its simplest form, additive manufacturing is the process of building your parts by adding material, as opposed to manufacturing processes like CNC, whereby you need to remove material from a solid piece to create your part.

When it comes to 3D printing, there are several different types that all produce varying results depending on your budget.

- FDM – Fused deposition modeling, is a 3D printing process that uses a continuous filament of a thermoplastic material. The filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on a work platform.

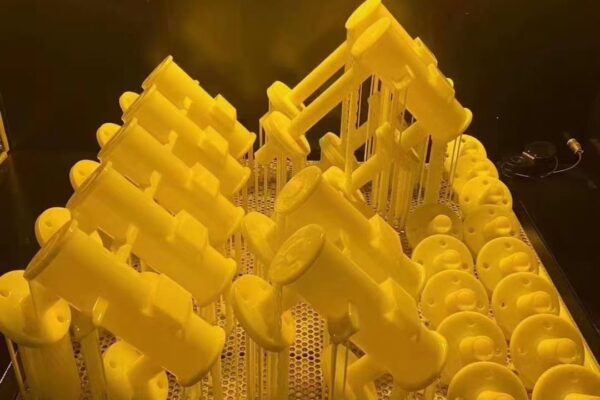

- SLA – Stereolithography printing is an early and widely used 3D printing technology. It uses ultraviolet light to cure photosensitive polymers.

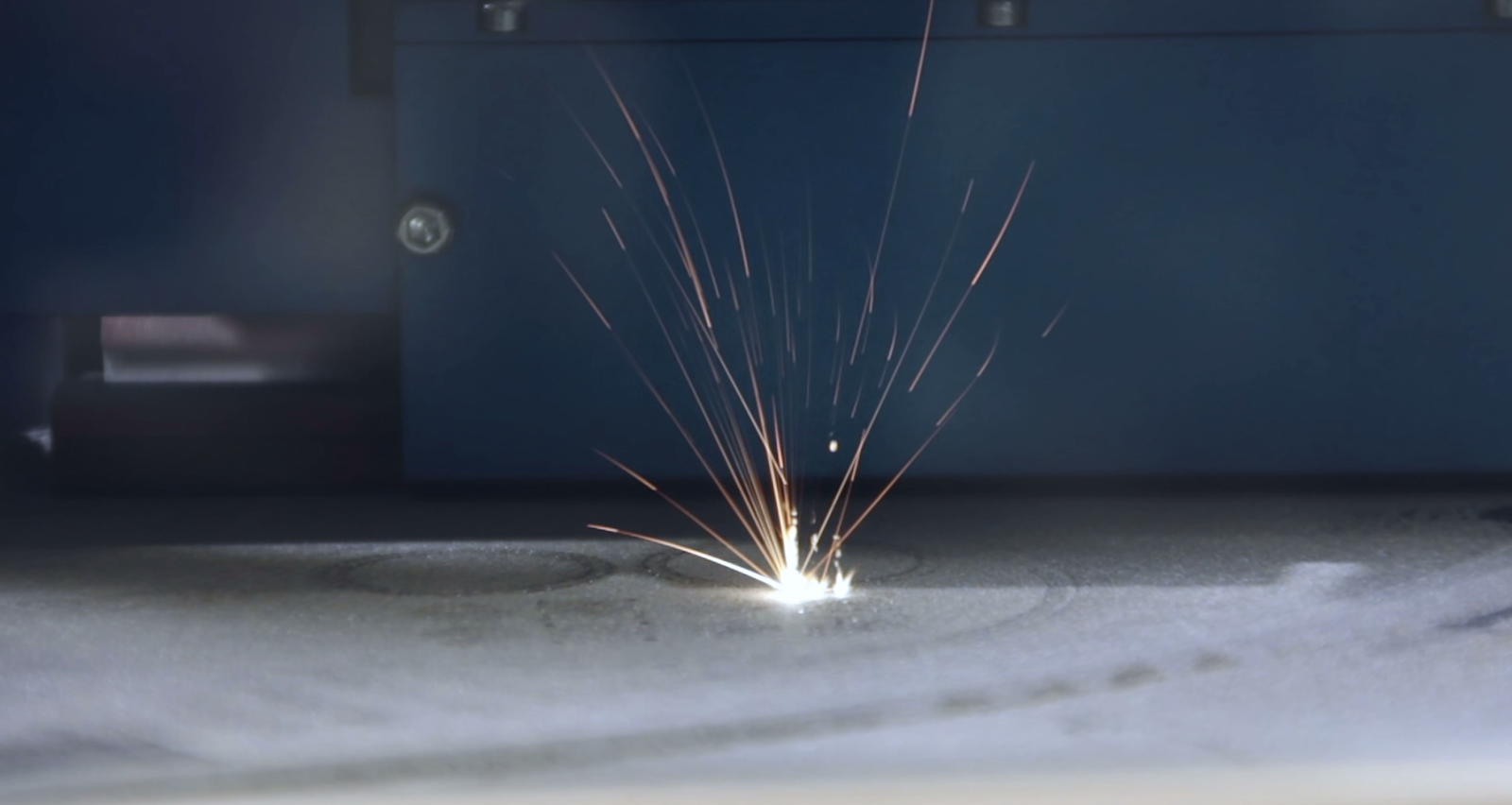

- SLS – Selective laser sintering uses a bed of powder and a highly precise laser to fuse layers together. It provides very precise parts with a high degree of finish.

- SLM – Selective laser melting uses a bed of powder similar to SLS printing, but instead of thermoplastic it’s high-powered laser fuses powdered alloy such as steel and titanium.

Our team is skilled in all areas of rapid prototyping, and we can quickly and easily help you turn your ideas into reality and select the best additive manufacturing method for your particular needs.

Send us your STEP files and we can quickly put together a quotation for you and turn around your parts in a matter of days. We can provide many finishing options, such as painting, sandblasting, powder coating, and more.